Maximize Heat Transfer

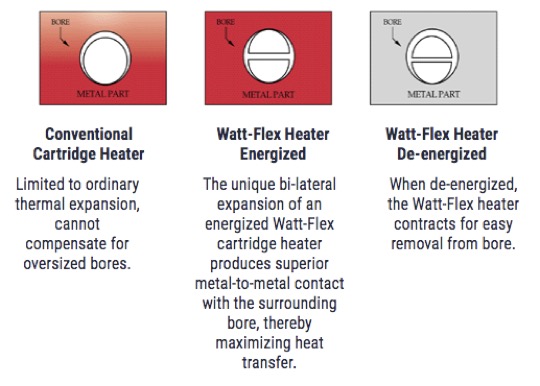

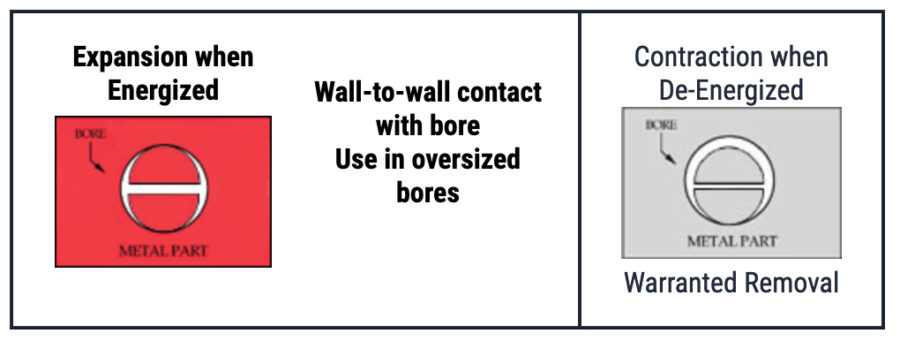

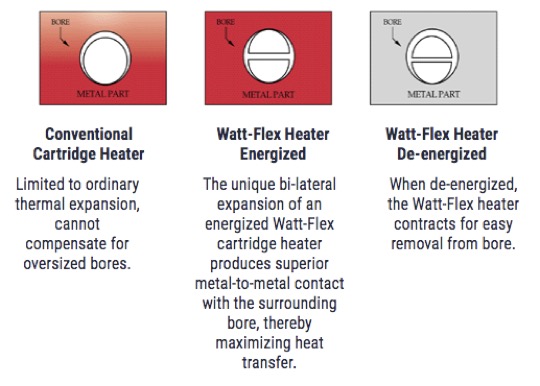

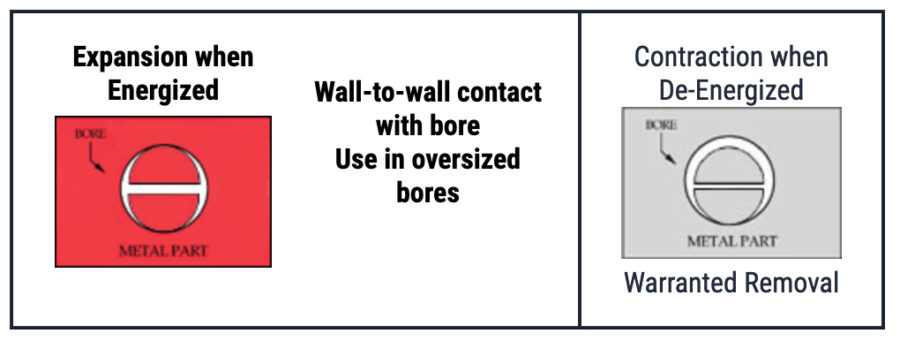

Watt-Flex Cartridge Heaters offer a unique split-sheath design that enables independent, bilateral expansion of each half of the heater outward against the walls of the surrounding bore. This innovative design provides exceptional benefits for customers:

Superior Heat Transfer: The close contact between the heater and the bore ensures efficient heat transfer, maximizing the effectiveness of your heating process.

More Uniform Process Heat: The consistent heat transfer across the entire length of the heater minimizes temperature variations, resulting in more uniform process heat distribution.

Greater Efficiency: Improved heat transfer translates to reduced energy consumption, lowering your operating costs and environmental impact.

Reduced Electricity Consumption: By maximizing heat transfer and efficiency, Watt-Flex Cartridge Heaters minimize the amount of electricity required to achieve your desired heating goals.

Effective Heating in Oversized Bores: Even if your bores are oversized due to previous use or drill-outs, the bilateral sheath expansion of Watt-Flex Cartridge Heaters ensures maximum contact for optimal conduction heating.

Unmatched Performance for Your Heating Applications

Watt-Flex Cartridge Heaters are the ideal solution for a wide range of heating applications, delivering unmatched performance and significant cost savings. Their unique split-sheath design and superior heat transfer capabilities make them the preferred choice for industries that demand the highest standards in efficiency and effectiveness.

Invest in Watt-Flex Cartridge Heaters and experience the difference:

Reduced Energy Costs: Lower your electricity consumption and minimize your carbon footprint.

Enhanced Process Quality: Enjoy more uniform process heat distribution for consistent results.

Extended Heater Lifespan: Benefit from improved heat transfer and reduced thermal stress, leading to longer heater life.

Simplified Maintenance: Eliminate bore seizure and avoid costly drill-outs.

Peace of Mind: Enjoy the confidence of using industry-leading cartridge heaters backed by a reputable manufacturer.

Embrace the future of efficient and effective heating with Watt-Flex Cartridge Heaters. Contact us today to discuss your specific application requirements and discover how Watt-Flex can elevate your heating processes to new heights.

High Watt Density

Watt-Flex Cartridge Heaters: Break Through the Limits of Conventional Heating

Watt-Flex cartridge heaters offer a dramatic leap in heating performance, delivering up to 50% higher warrantable watt densities and operating temperatures up to 1832°F (1000°C). This unprecedented performance is made possible by Dalton Electric’s innovative design and manufacturing techniques.

Advanced Materials and Construction

Watt-Flex cartridge heaters are constructed with the highest quality materials, including:

- Incoloy sheath for superior corrosion resistance and strength

- High-purity magnesium oxide for optimal electrical insulation and heat transfer

- Nickel chromium resistance wire for durability and consistent performance

- Stainless steel terminals for secure connections

Proprietary Manufacturing Processes

Dalton Electric’s proprietary manufacturing processes ensure that Watt-Flex cartridge heaters are built to the most exacting standards. Our unique magnesium oxide (MgO) filling process creates extreme compaction. This eliminates the need for a ceramic core, which can be a source of failure in conventional heaters. The highly compacted magnesium oxide provides superior dielectric strength and increases heat transfer to the tool, resulting in higher watt densities, operating temperatures, and longer heater life.

Benefits of Watt-Flex Cartridge Heaters

- Higher warrantable watt densities and operating temperatures

- More efficient operation

- Longer heater life

- Simpler and faster replacement

- Reduced downtime and maintenance costs

- Improved process quality and consistency

Applications

Watt-Flex cartridge heaters are ideal for a wide range of demanding applications, including:

- Higher warrantable watt densities and operating temperatures

- More efficient operation

- Longer heater life

- Simpler and faster replacement

- Reduced downtime and maintenance costs

- Improved process quality and consistency

Conclusion

Watt-Flex cartridge heaters offer a clear advantage over conventional heaters, delivering superior performance, reliability, and efficiency. If you are looking for the best possible heating solution for your application, Watt-Flex cartridge heaters are the clear choice.

Distributive Wattage

Customized Heating Profile with Distributed Wattage Technology

Precision heat where you need it with Watt-Flex Cartridge Heaters, featuring distributed wattage technology that allows for temperature “zone” profile to fit your specific requirements. Unlike conventional cartridge heaters with uniform watt-density, Watt-Flex heaters offer the flexibility to vary the wattage along the length of the heater, creating customized zones of heat. This innovative technology unlocks a range of benefits for customers:

Precision Temperature Control: Achieve temperature uniformity by compensating for areas of higher or lower heat loss over the heater’s length.

Enhanced Process Efficiency: Optimize heating performance in applications where heat loss occurs at the edges or center of the platen, ensuring consistent process temperatures throughout.

Improved Material Processing: Achieve precise temperature control for heat-sensitive materials, preventing degradation, scrap parts and ensuring consistent product quality.

Customized Solutions for Unique Applications: Tailor the temperature profile to meet the specific needs of your application, whether it’s compensating for heat loss in large platens or creating precise temperature zones for complex processes.

Unlocking a World of Possibilities with Distributed Wattage

Watt-Flex Cartridge Heaters with distributed wattage technology empower you to:

Optimize Heating Performance: Achieve the ideal temperature distribution for your specific application, maximizing efficiency and process quality.

Minimize Heat Loss: Compensate for areas of heat loss, ensuring consistent temperatures across the entire platen or heating element.

Handle Heat-Sensitive Materials: Process heat-sensitive materials with confidence, preventing degradation and ensuring product consistency.

Tailor Heating Profiles: Create customized temperature profiles to meet the unique requirements of your application.

Experience the Difference with Watt-Flex Cartridge Heaters

Elevate your heating processes to new heights of precision and control with Watt-Flex Cartridge Heaters and their advanced distributed wattage technology. With the ability to tailor the temperature profile to your specific needs, you’ll achieve optimal heating performance, enhanced process efficiency, and superior product quality.

Partner with Dalton Electric and discover the power of customized heating solutions.

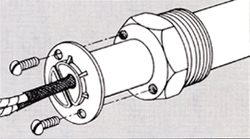

Protected Lead Wires

Watt-Flex Cartridge Heaters: Robust Lead Wire Protection for Demanding Applications

Watt-Flex cartridge heaters feature rugged lead wire protection that shields against abrasion, corrosion, and other hazards. This is essential in demanding industrial environments where heaters are subjected to machine cycling, harsh chemicals, and rough handling.

Watt-Flex headers are constructed of high-quality stainless steel to provide long-lasting protection. Two options are available:

- Stainless steel braid: Flexible with a tighter bend radius, providing excellent flexibility and strength.

- Stainless steel BX: Interlocking hose that offers greater strength and abrasion protection than braid, at a slightly lower cost.

Straight and right-angle headers are available to accommodate a variety of installation requirements.

Benefits of Watt-Flex Lead Wire Protection

- Extended lead wire life

- Reduced downtime and maintenance costs

- Improved reliability and performance

- Enhanced safety

End Bore Seizures

Ease of removal/bore seizure

Watt-Flex Cartridge Heaters: Eliminate Bore Seizure with Patented Split-Sheath Design

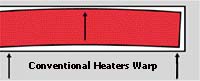

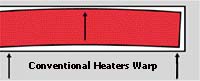

Conventional cartridge heaters can warp and bind inside bores, leading to costly downtime and replacement costs. This is caused by temperature differentials within the heater, which can cause it to bow.

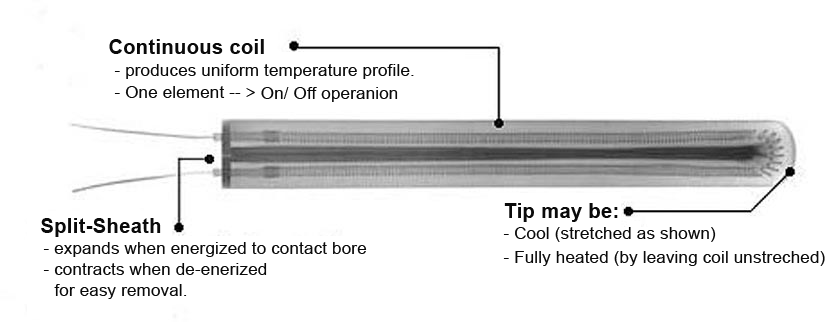

Dalton Electric’s Watt-Flex cartridge heaters feature a patented split-sheath design that eliminates bore seizure. The split sheath allows each half of the heater to expand and contract independently, ensuring that the heater always maintains intimate contact with the bore wall. This prevents the heater from warping or binding, even after repeated heating and cooling cycles.

Benefits of Watt-Flex Cartridge Heaters:

- Eliminate bore seizure and costly downtime

- Reduce replacement costs

- Extend heater lifespan

- Improve heat transfer efficiency

- Increase reliability

The unique bi-lateral expansion of Watt-Flex cartridge heaters eliminates the need for tight fits and makes them well-suited for use in oversized bores where conventional cartridge heaters cannot be used effectively.

Cartridge heater fit is measured as the difference between the inside diameter (I.D.) of the bore and the outside dimension (O.D.) of the heater.

The suggested fit for a Watt-Flex Cartridge Heater is .010″ greater than the nominal Watt-Flex heater sheath diameter.

For example, the ideal bore diameter for a 1/2″ diameter Watt-Flex heater (0.495” nominal) would be 0.502 –> 0.505″. At the maximum tolerance dimension of the heater (0.497”) and the minimum bore diameter, the heater would have a 0.005″ fit, allowing ease of insertion and removal.

Generally, smaller diameter heaters benefit from a tighter fit and fit can be loosened for larger diameters.

Contact Dalton Electric today to learn more about how Watt-Flex cartridge heaters can help you improve your process heating operation.

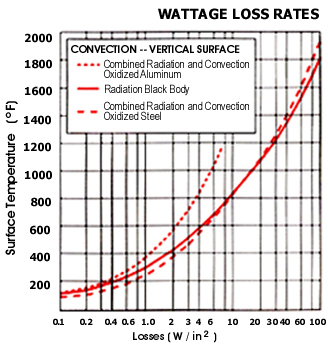

Reduce the Cost of Heating

Reduce total cost of process heating by an average of 40%

Revolutionize Your Process Heating Efficiency with Watt-Flex Cartridge Heaters

In the realm of process heating, efficiency is paramount. Watt-Flex Cartridge Heaters, pioneered by Dalton Electric, are engineered to redefine your heating operations, delivering exceptional performance and substantial cost savings. Their unique split-sheath design and cutting-edge manufacturing techniques set a new standard for energy optimization, reducing your total cost of process heating by an average of 40% compared to conventional heaters.

Unleashing the Power of Enhanced Heat Transfer

At the heart of Watt-Flex Cartridge Heaters lies a patented split-sheath design that revolutionizes heat transfer efficiency. Unlike conventional cartridge heaters that rely on a ceramic core, Watt-Flex heaters expand when energized, allowing for greater contact with the surrounding bore. This bilateral expansion maximizes heat transfer, ensuring that every watt of energy is effectively utilized to achieve your desired heating goals.

Unlocking Cost Savings

The superior heat transfer capabilities of Watt-Flex Cartridge Heaters allow users to reach set temperature faster and reduce cycle times. This translates into higher productivity, lower energy costs, improved environmental footprint, and higher overall profitability of your business.

Reap the Benefits of Unparalleled Performance

Watt-Flex Cartridge Heaters offer a multitude of benefits that extend beyond energy efficiency:

Uniform Process Heat Distribution: Experience consistent heating across the entire length of the heater, ensuring optimal process quality.

Extended Heater Lifespan: Benefit from reduced thermal stress and improved heat transfer, leading to longer heater life and minimized maintenance costs.

Eliminated Bore Seizure: Avoid costly drill-outs and downtime with the unique split-sheath design that prevents bore seizure.

Enhanced Productivity: Achieve faster heating times and improved process efficiency.

Reduced Environmental Impact: Minimize your carbon footprint with lower energy consumption.

Embrace the Future of Efficient Process Heating

Watt-Flex Cartridge Heaters are the pinnacle of innovation and efficiency, offering a transformative solution for your process heating needs. With their patented split-sheath design, exceptional heat transfer capabilities, and a host of other benefits, Watt-Flex Cartridge Heaters are poised to revolutionize your operations, delivering unparalleled performance and significant cost savings.

Partner with Dalton Electric and elevate your heating processes to new heights of efficiency and effectiveness.

Increase Life Span

Watt-Flex Cartridge Heaters: Extended Service Life Through Superior Heat Transfer and Design

Watt-Flex cartridge heaters offer a dramatic increase in service life, lasting up to 5 times longer than conventional heaters. This is achieved through a combination of superior heat transfer and design features.

Enhanced Heat Transfer

Watt-Flex cartridge heaters feature high-purity magnesium oxide (MgO) dielectric that is compacted to extreme density. This ensures maximum heat transfer away from the coil to the heater sheath. Additionally, the energized split-sheath expands to create intimate contact with the bore wall, further improving heat transfer.

Superior Insulation Protection

Higher compaction provides greater insulation protection to the coil further contributing to long heater life.

Split Sheath creates Intimate Contact with Bore Wall

The split sheath design of Watt-Flex cartridge heaters allows the legs of the heaters to independently expand into the bore wall. This unique capability prevents hot spots and premature burnout that is more commonly found with conventional heaters due to their poor contact to the bore wall.

Benefits of Watt-Flex Cartridge Heaters

- Extended service life

- Reduced downtime

- Lower operating costs

- More efficient heat transfer

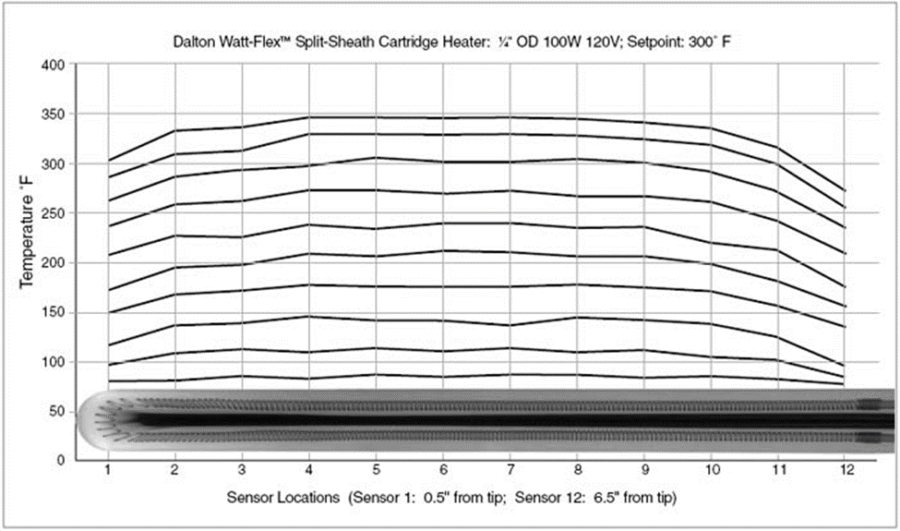

- Uniform temperature profile

- Reduced risk of burnout

Conclusion

Watt-Flex cartridge heaters offer a significant advantage over conventional heaters in terms of service life. With their superior heat transfer and design features, Watt-Flex heaters can last up to 5 times longer, resulting in reduced downtime and lower operating costs.

Uniform Temperature Profile

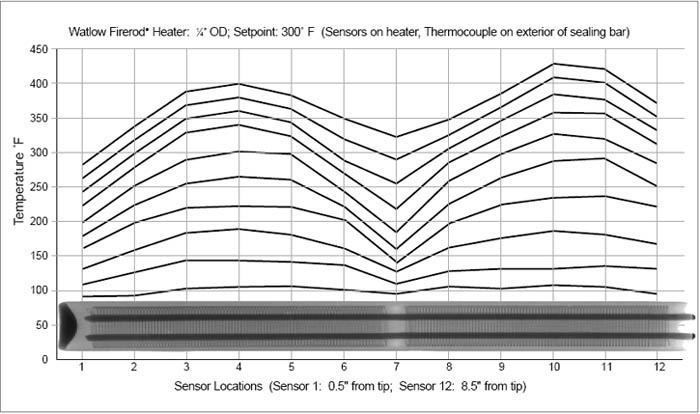

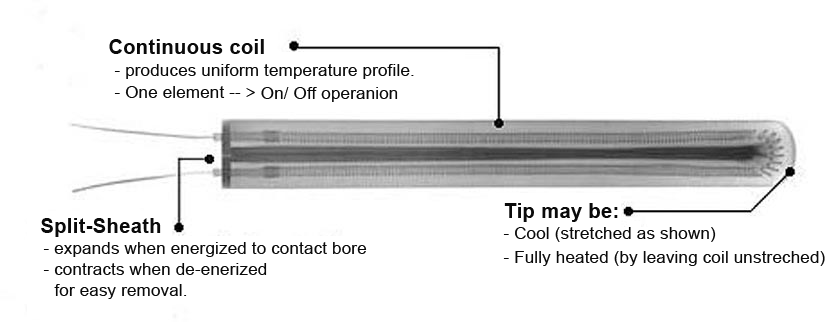

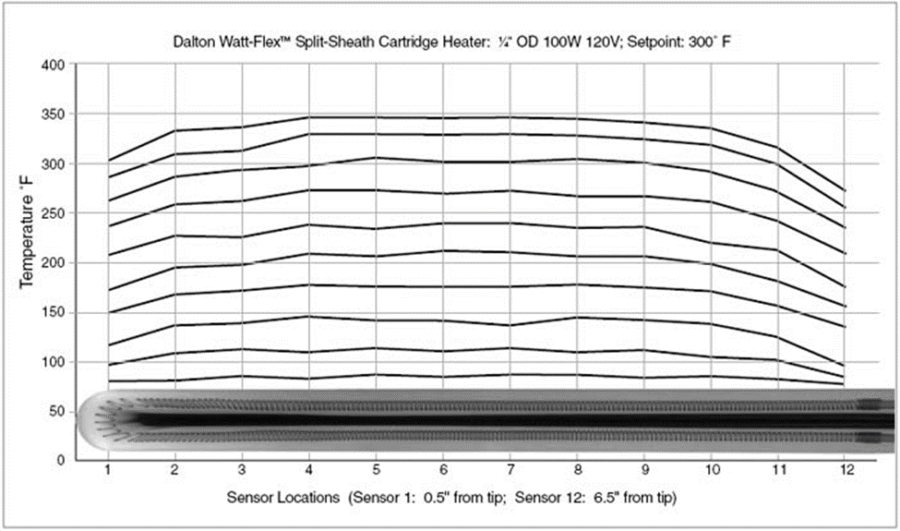

The continuous coil in the Watt-Flex® cartridge heater produces an even temperature along the length of the sheath.

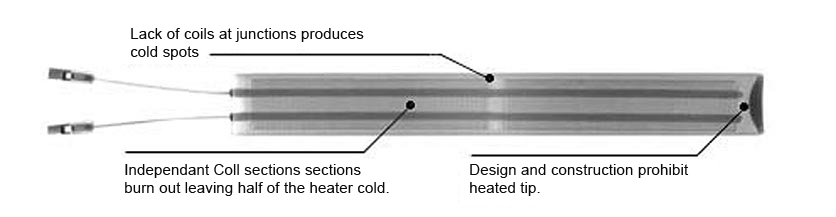

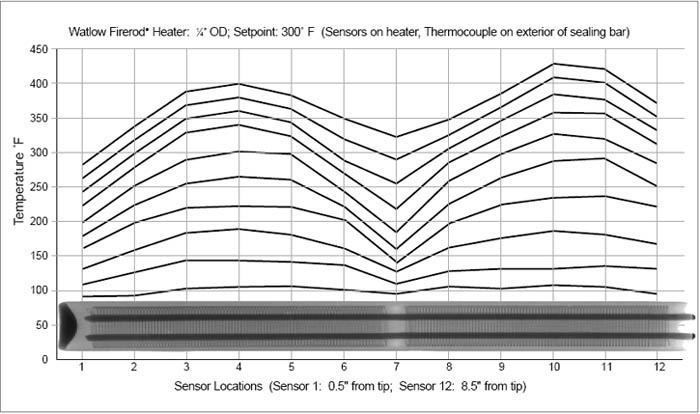

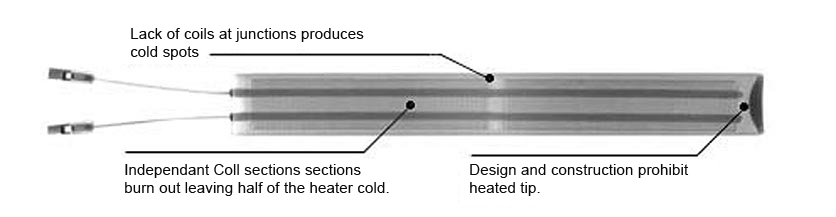

Competitor’s Sectional Heater Results In Cold Spots and Uneven Temperature Profile

Competitor’s Sectional Heater Results In Cold Spots and Uneven Temperature Profile

This heat profile of a conventional cartridge heater was generated by a customer. Note that the two cores in this heater produce about 75° F higher temperatures than the cold junction between them.

Eliminate Uneven Heating

Achieve Precision Temperature Control with Watt-Flex Cartridge Heaters

Harness the power of precise temperature control with Watt-Flex Cartridge Heaters, engineered to deliver unparalleled temperature uniformity and customization for demanding applications. Unlike conventional cartridge heaters that produce inconsistent heat distribution, Watt-Flex heaters utilize a continuous heating coil, ensuring a uniform temperature profile along the entire length of the heater. This translates into a host of benefits for customers:

Uniform Temperature Profile: Experience consistent heat distribution across the entire heater, eliminating temperature fluctuations that can compromise product quality.

Customized Temperature Profiles: Tailor the temperature profile to your specific needs by varying the watt-density, creating customized zones of heat along the heater.

Optimized Material Processing: Achieve optimal results when molding heat-sensitive plastics, where precise temperature control is critical to prevent material degradation and ensure consistent product quality.

Superior Temperature Control for Heat-Sensitive Plastics

The superior temperature uniformity of Watt-Flex Cartridge Heaters is particularly advantageous when molding, sealing or extruding heat-sensitive plastics. These materials often have a narrow temperature window to process. With Watt-Flex heaters, you can maintain precise temperature control within this critical range, preventing material degradation and ensuring consistent product quality.

Elevating Your Heating Processes with Precision and Control

Watt-Flex Cartridge Heaters temperature control capabilities unlock a multitude of benefits:

Enhanced Product Quality: Eliminate temperature inconsistencies that can lead to defects and product failures.

Optimized Process Efficiency: Achieve faster heating times and reduced cycle times, boosting productivity.

Reduced Material Waste: Prevent material degradation and minimize scrap rates, saving costs.

Expanded Material Compatibility: Handle a wider range of heat-sensitive materials with confidence.

Experience the Difference with Watt-Flex Cartridge Heaters

Upgrade your heating processes with Watt-Flex Cartridge Heaters and experience the benefits of precision temperature control. Their continuous heating coil technology and customizable watt-density deliver unparalleled temperature uniformity, ensuring optimal results for even the most demanding applications.

Partner with Dalton Electric and elevate your heating processes to new heights of precision and control.

Prevent Contamination

Secure Your Profits with Innovative Heater Protection Solutions

Water and other contaminants can wreak havoc on heaters, leading to costly downtime and lost productivity. Dalton Electric’s innovative protection solutions safeguard your heaters from even the most challenging environments, including chemical washdowns, oil-rich food processing applications, and high-pressure cleaning.

Three Options to Choose From:

Option 1: Water Protection Solution

- Full weld around header

- RTV potting with MW transition and FX wire

Option 2: Next Level Solution

- Sealed collar with full weld around header

- RTV potting with Teflon or FX wire

Option 3: Ultimate Water Prevention Solution

- BX-5 convolute

- Fully potted header

Benefits:

- Prevent costly downtime and lost productivity

- Safeguard heaters from even the most challenging environments

- Extend heater lifespan

- Reduce maintenance costs

- Ensure optimal performance and reliability

Contact Dalton Electric today to learn more about our innovative heater protection solutions.

Competitor’s Sectional Heater Results In Cold Spots and Uneven Temperature Profile

Competitor’s Sectional Heater Results In Cold Spots and Uneven Temperature Profile